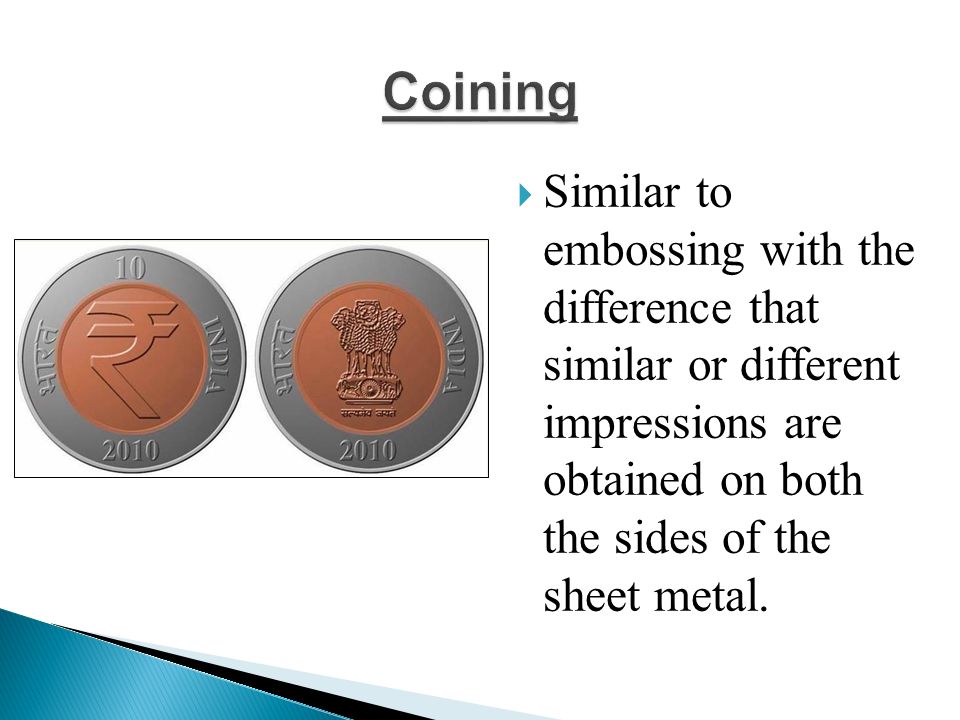

A beneficial feature is that in some metals the plastic flow reduces surface grain size and work hardens the surface while the material deeper in the part retains its toughness and ductility the term comes from the initial use of the.

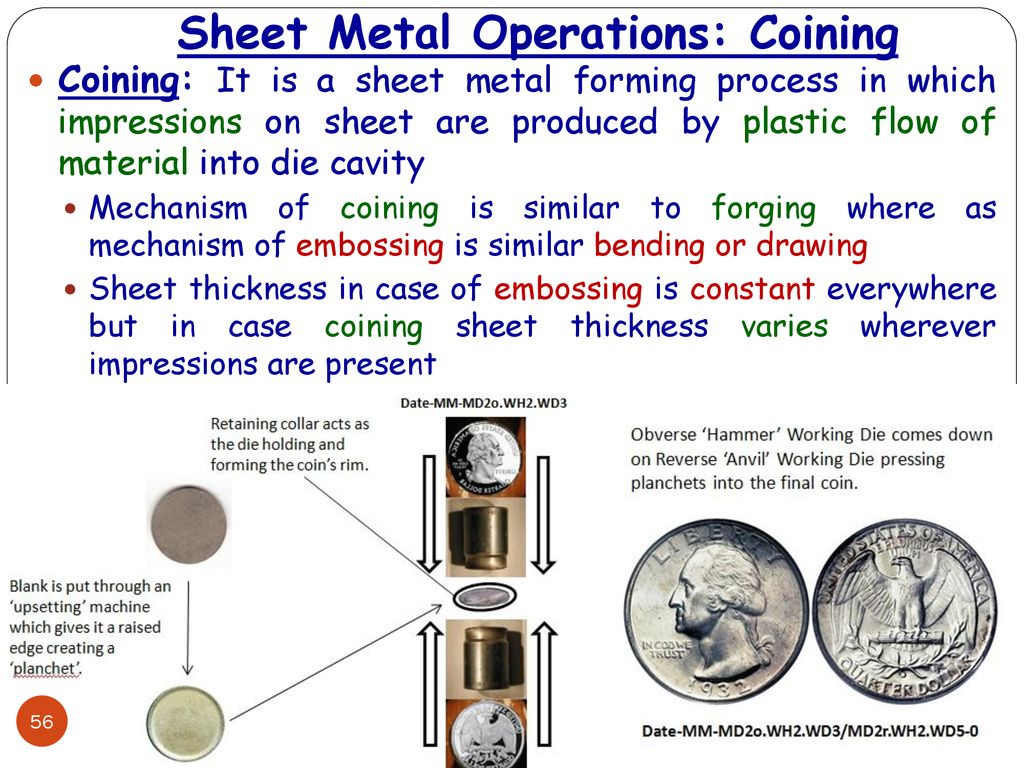

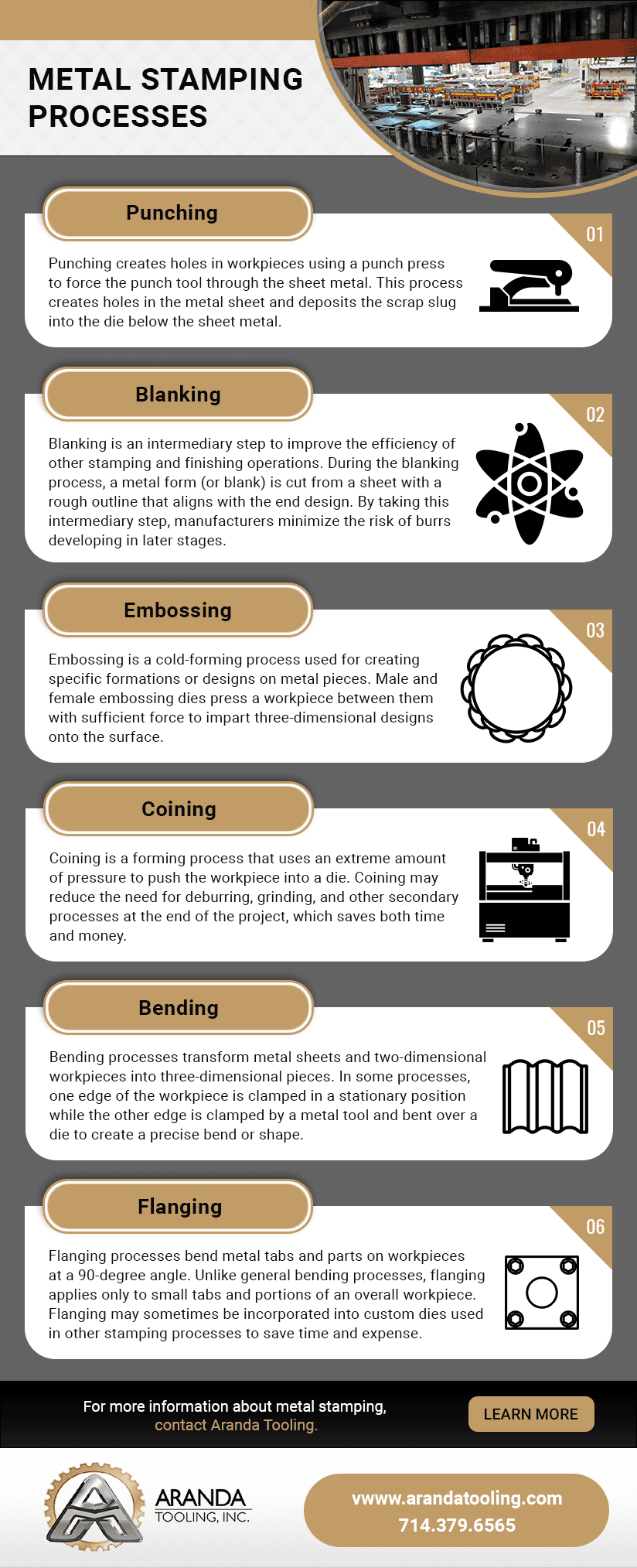

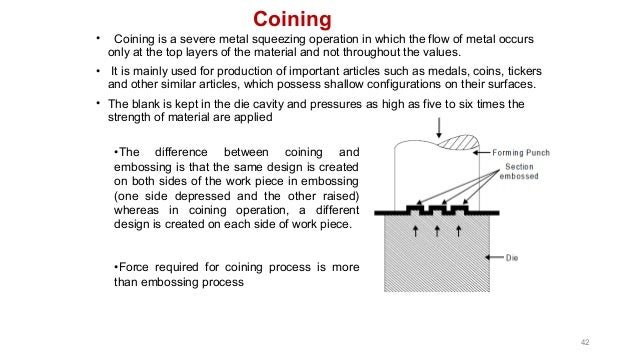

Coining operation in sheet metal.

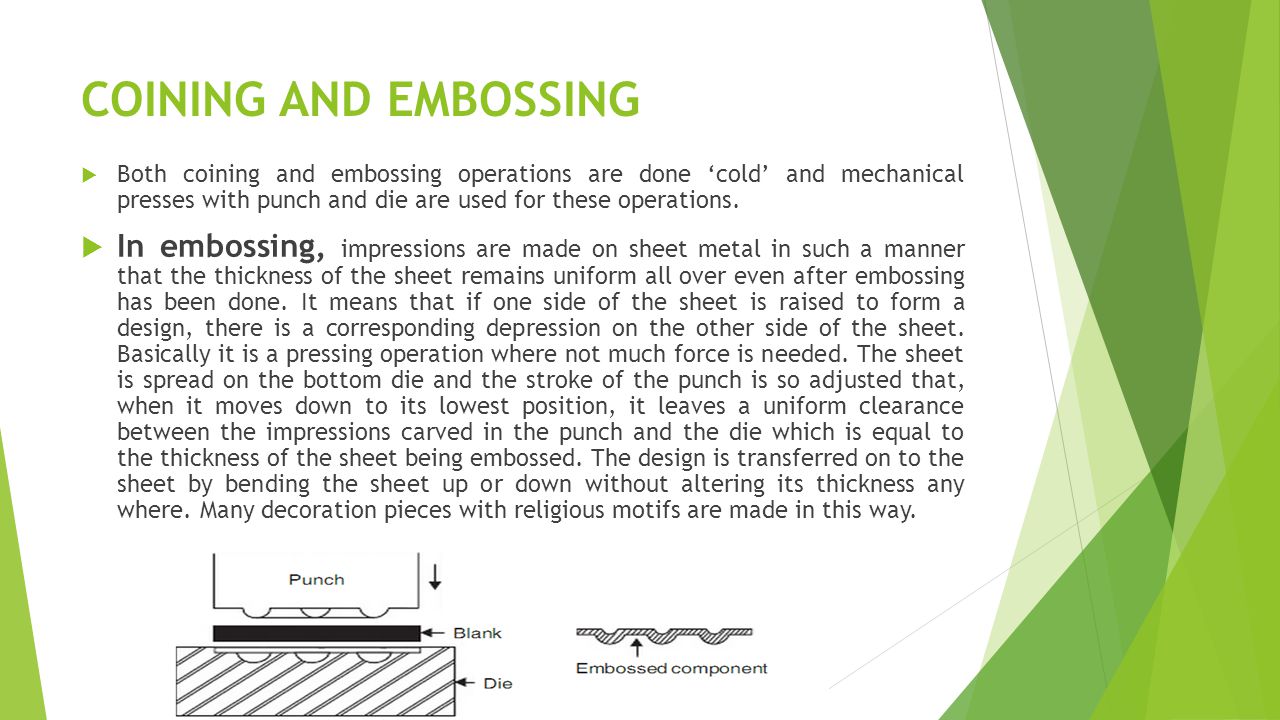

Coining also can reduce the metal thickness.

It is a metal forming operation in which the straight metal sheet is transformed into a curved form.

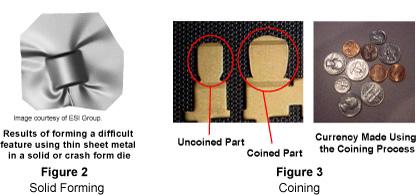

Coins metal currency are created with the coining process.

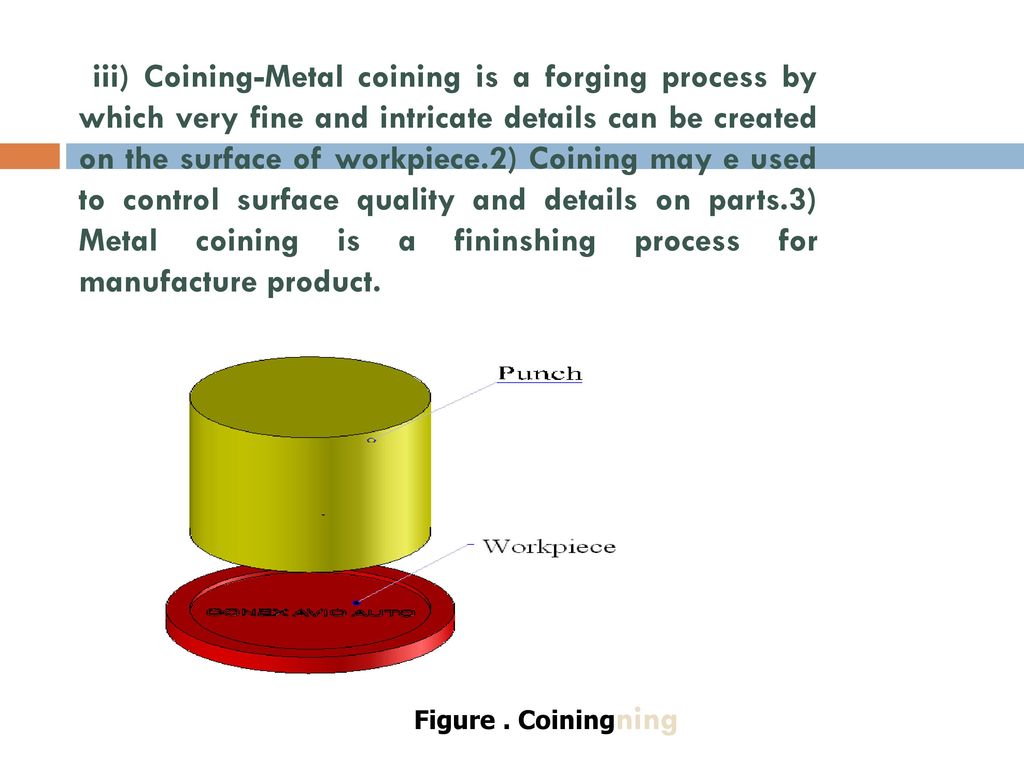

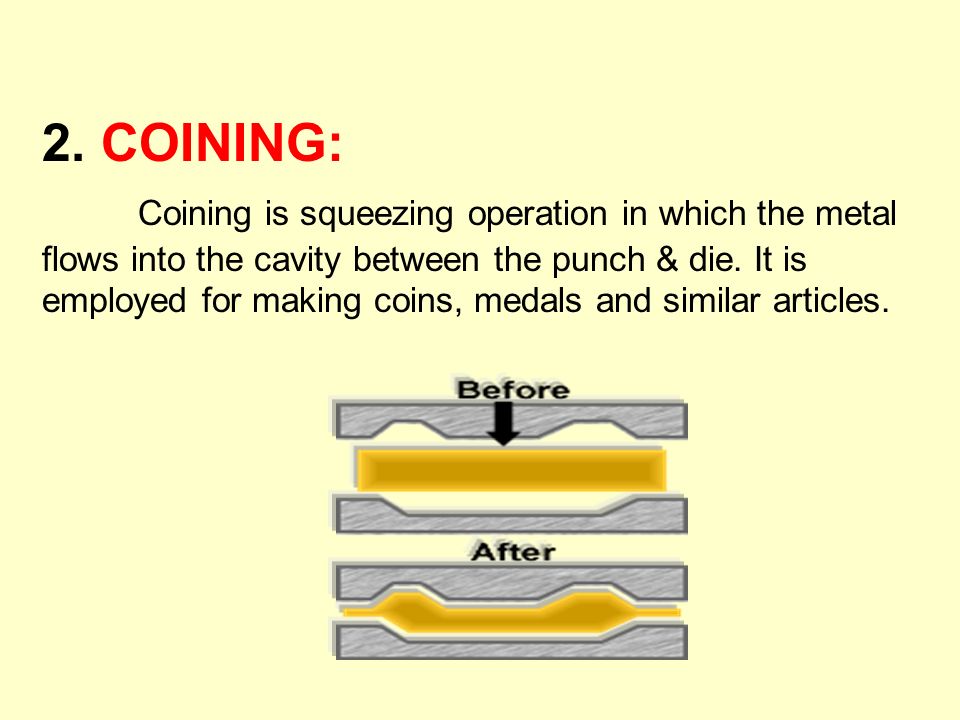

It is a process of pressing metal in a die so that it flows into the die space.

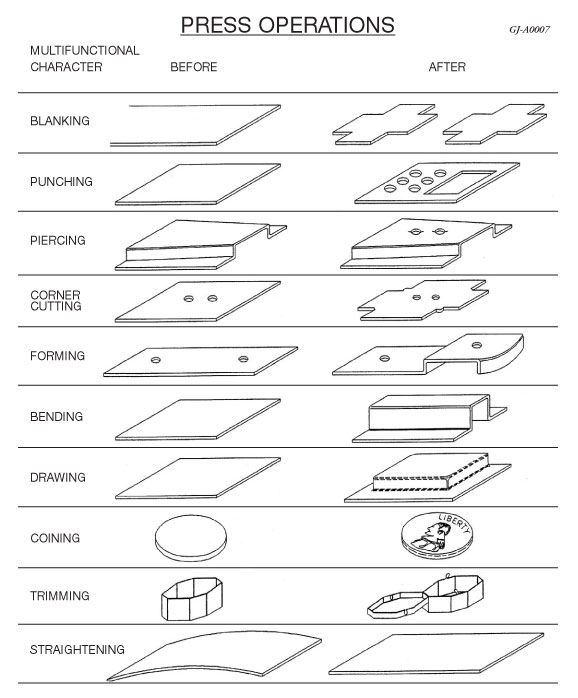

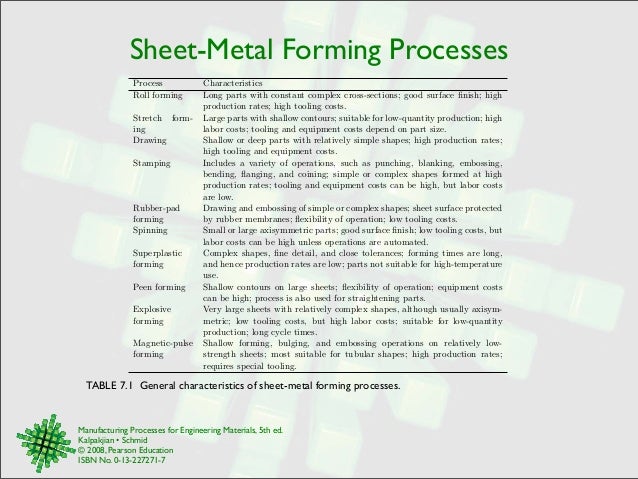

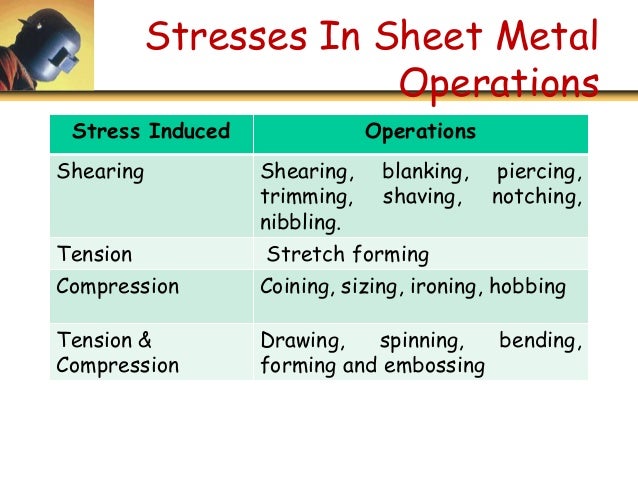

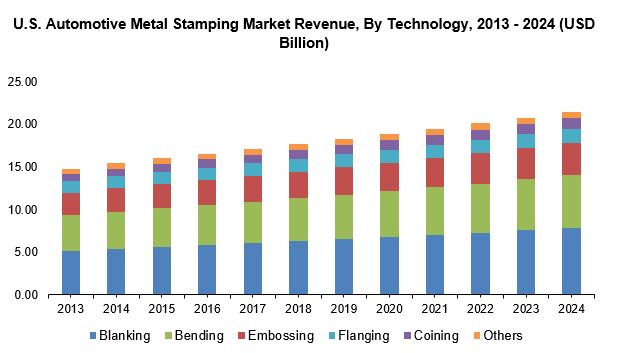

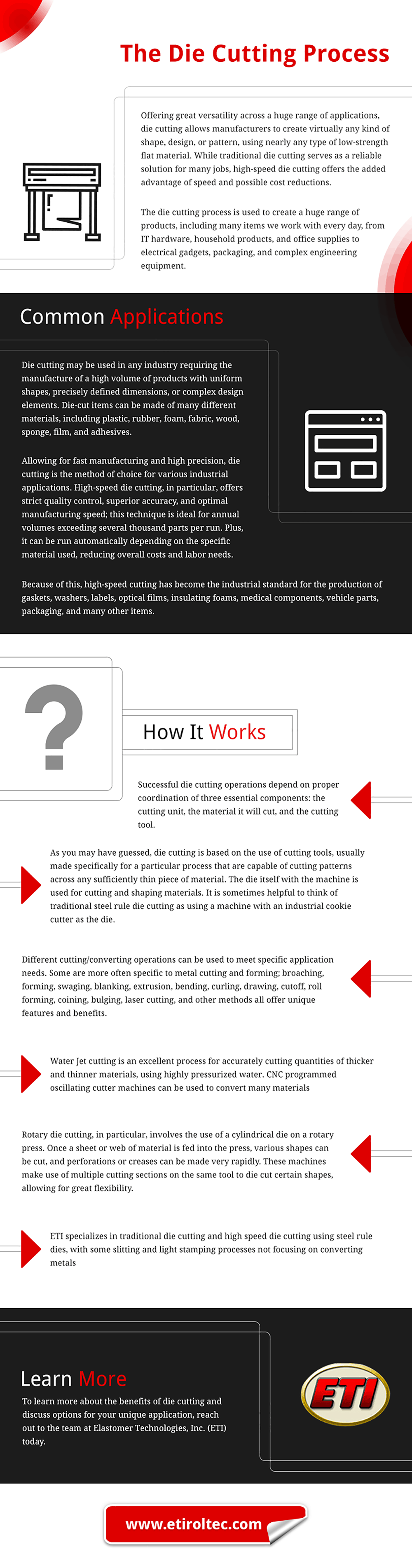

Shear shearing blanking piercing and trimming 2.

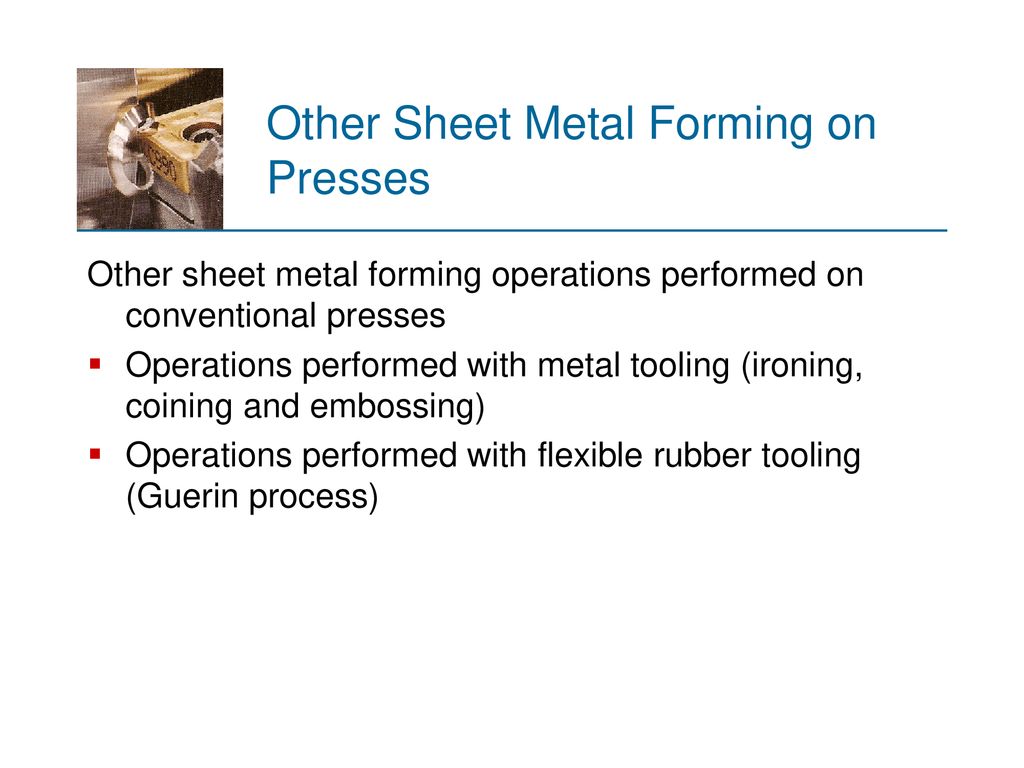

How are bending flanging coining embossing stretching curling hemming ironing necking and drawing related.

The sheet metal operation depending on the type of stress induced.

There is little if any spring back.

The operation is carried out mostly for the purpose of stiffening flat panels the operation is also sometimes used for making.

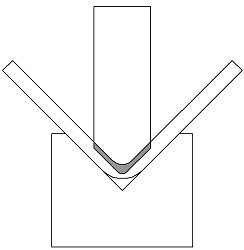

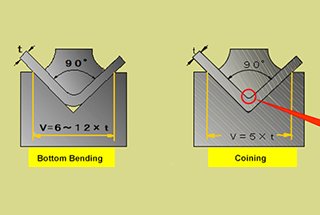

The theory behind coining is that with enough tonnage your sheet metal will bend to the precise angle of your tooling so your tooling should be an equal match to.

They all are common metal forming operations.

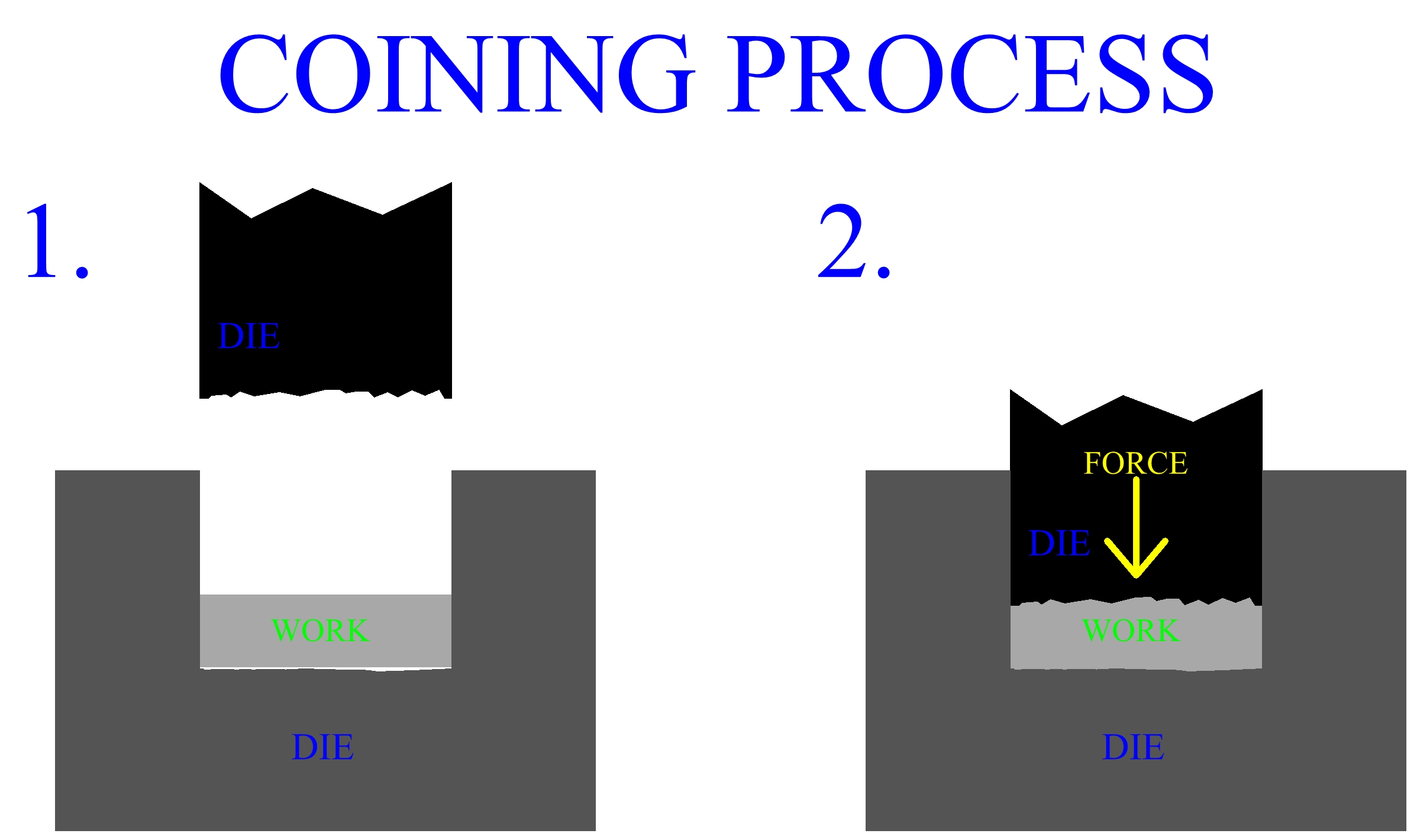

In coining the top tool forces the material into the bottom die with 5 to 30 times the force of air bending causing permanent deformation through the sheet.

Find out more about these processes in this final installment of stamping expert art hedrick s sheet metal stamping series.

In bending operations the sheet metal is subjected to both tensile and compressive stresses.

For example medals coins and jewellery.

Metal forming operations include following operations.

Coining sheet metal coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die.

Coining can produce an inside radius as low as 0 4 t with a 5 t width of the v opening.

A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it see figure 3.

Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure.

In coining the sheet metal is more than just bent it is actually thinned by the impact of the punch and die as it is compressed between them along the bending surfaces fig.

Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material.