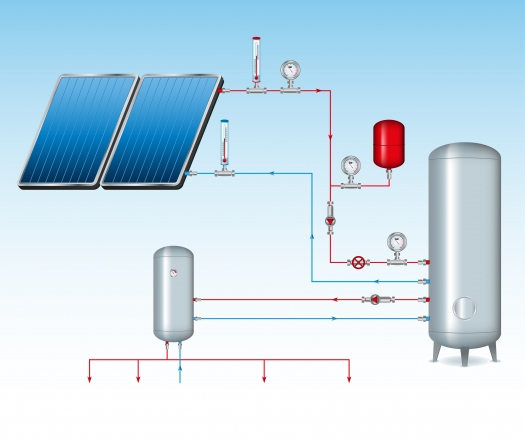

The system diagram shown in figure 2 in which the entire assembly contains a heat transfer fluid 3 a heating element an electric element 1 and one of the boundary walls of this fluid is also a heat exchange surface with the heat consumer 2 should be considered as a heat exchange system without an intermediate system or circuit.

Thermal fluid heater working principle pdf.

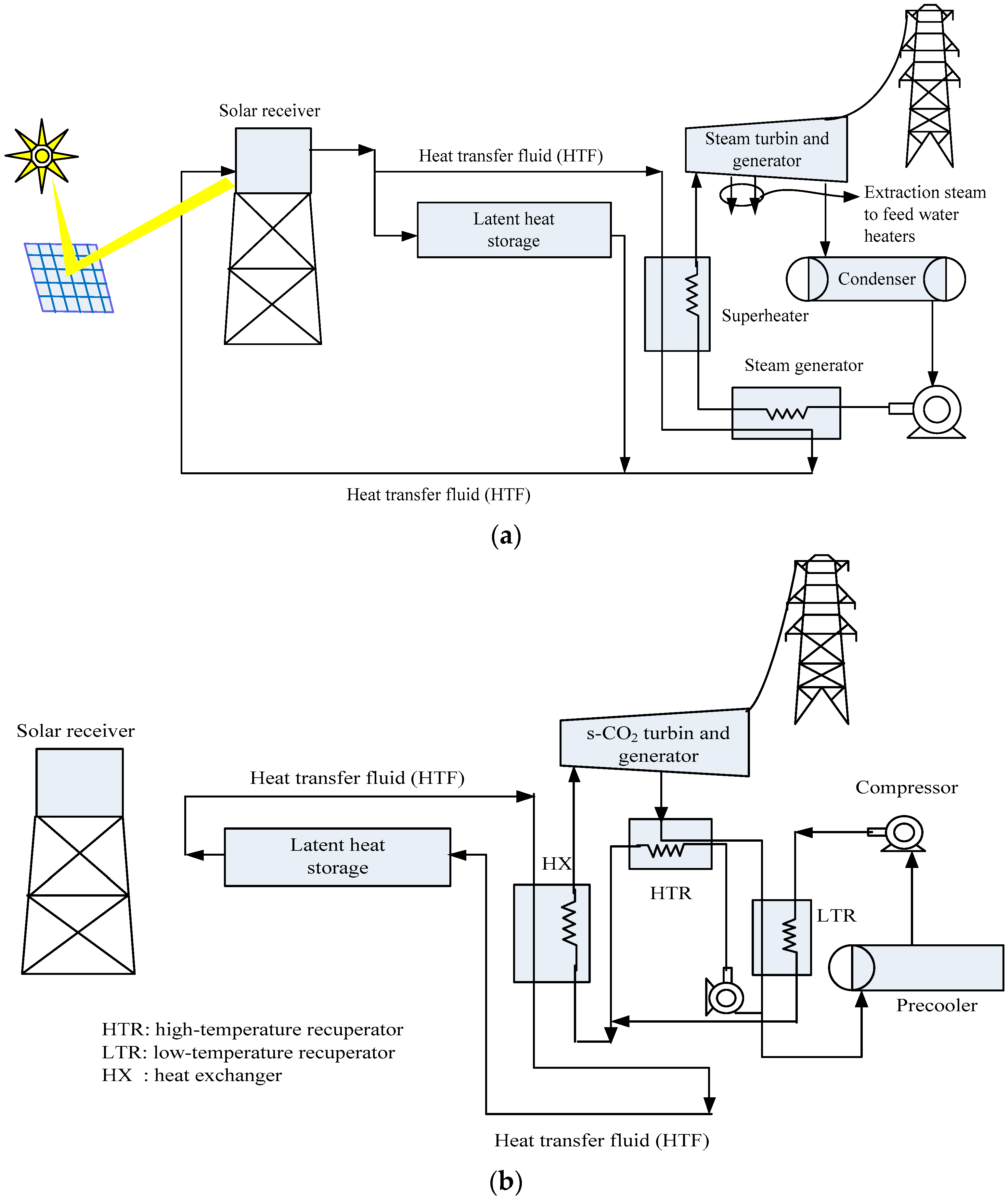

The working fluid currently used in cstp plants with ptc is a thermal oil composed of an eutectic mixture of two very stable compounds.

A regenerative heat exchanger or more commonly a regenerator is a type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid.

To accomplish this the hot fluid is brought into contact with the heat storage medium then the fluid is displaced with the cold fluid which absorbs the heat.

Steam a thermal fluid hot oil system operates in a closed loop circulation system with minimal pressure.

Applicability of csd 1 to thermal fluid systems.

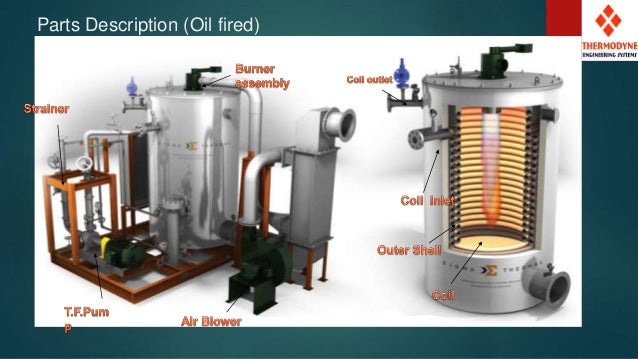

How hot oil heaters work.

Combustion controls covered in csd 1 are applicable to thermal fluid heaters.

A task group was formed in csd 1 to review and define the specific requirements for thermal fluid systems.

Fulton thermal fluid systems can reach 750 f 345 c making them an ideal choice for many process heat applications.

Components of sufficient strength are then chosen and the heater is constructed.

Thermal oil heaters operate on the same principle as their steam based counterparts.

High flow rate the higher life of thermic fluid heater coil.

This thermal oil has a maximum working temperature of 398 c and is stable with time so long as this maximum temperature is not surpassed and a.

5 9 2013 1 40 04 pm.

Academia edu is a platform for academics to share research papers.

Pdf setting thermal oil heater cdr author.

1 biphenyl c 12 h 10 and 2 diphenyl oxide c 12 h 10 o.

Thermal fluid system vent tank relief.

Fully automatic unit thermic fluid heater is fully automatic during the operation it maintains the desired temperature of a thermic fluid.

The thermal oil heater design process begins with the identification of the most appropriate setup for a given process system.

Higher system efficiency thermic fluid heater is simply in operation and no need to higher skills so it s reduced operating cost.

The reason why thermal oil heating becomes more and more used are mainly related to these features and arguments.

However part cw steam and waterside control does not cover the requirements for thermal fluid systems.